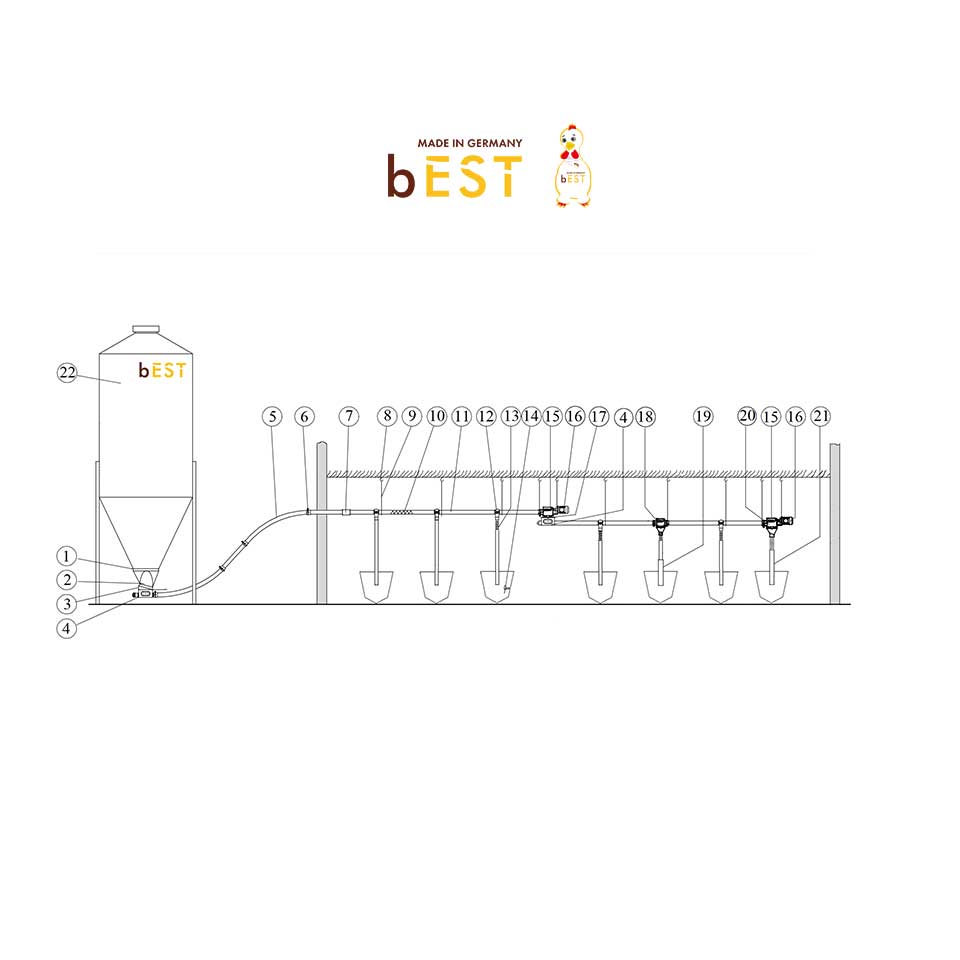

Cross conveyor ![]()

How does a cross conveyor system work?

The cross conveyor is a transport system that transports feed directly from the silo to the feed hoppers at the beginning of the feeding line

Feed transport starts automatically and is carried out by auger with a diameter fi 55mm, fi 75mm, fi 90mm or fi 125mm

If there is no feed in the last hopper, a capacitive sensor starts the conveyor. The auger takes the feed from the silo and distributes it until the last hopper in the building is fully filled. When the hoppers are full of feed, the sensor disconnects the power supply

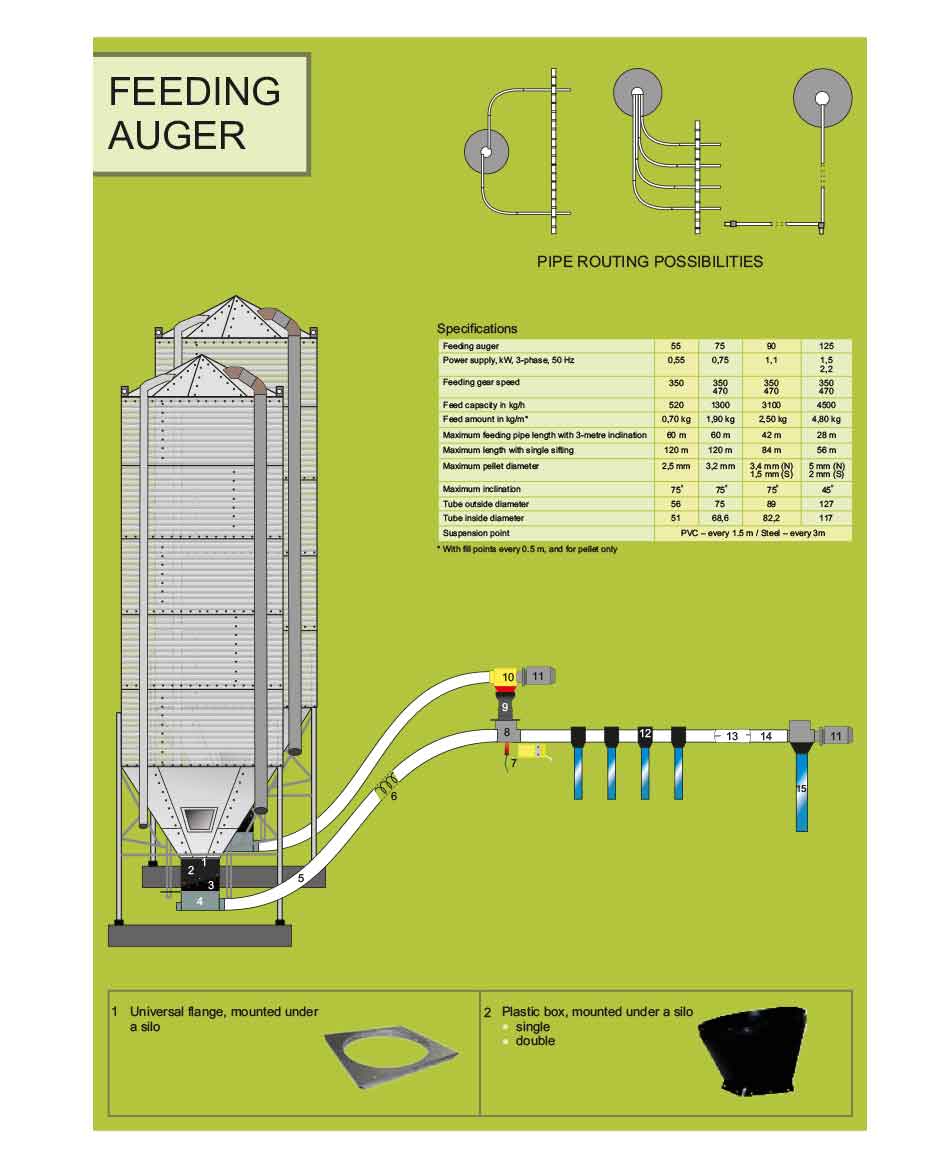

General technical information

Cross conveyor fi 55

Powerunit: 0.55kW

Feed capacity/amount: 520kg/h / 0.70kg/m

Maximum feed length: with 3m inclination 60m, with one extension boot 120m

Cross conveyor fi 75

Power unit: 0.75kW Feed capacity/amount: 1300kg/h / 1.90kg/m

Maximum feed length: with 3m inclination 60m, with one extension boot 120m

The length, diameter and power supply of cross conveyor depend on amount of birds and on the building conditions

General technical information

Cross conveyor fi 90

Power unit: 1.1kW or 1.5kW

Feed capacity/amount: 3100kg/h / 2.5kg/m

Maximum feed length: with 3m inclination42m, with one extension boot 84m

Cross conveyor fi 125

Power unit: 1.5kW/2.2kW

Feed capacity/amount: 4500kg/h / 4.8kg/m

Maximum feed length: with 3m inclination 28m, with one extension boot 56m

The length, diameter and power supply of cross conveyor depend on amount of birds and on the building conditions

To install the auger

Under the plastic upper boot is mounted a metal boot

- with a shaft connected with the auger, which moves the feed through the feed tubes

- or metal boot without shaft

Boots are made of high quality galvanized or stainless steel, single or double intake, matching the cross conveyor diameter fi 55mm, fi 75mm, fi 90mm and fi 125mm

PVC pipes and elbows

The metal boots are connected to the PVC pipes and elbows inside which the auger rotates into the building. The pipes and elbows, made in Germany, are made of strong and durable PVC material, resistant to weather conditions, UV rays, extreme temperaturesand mechanical abrasion and are neutral and safe for moving feed

Each pipe and elbow is finished with a muff on one side. Thanks that the each one next elements fit solidly and is possible to create a structure that rises upwards and runs under the ceiling across the building

Tubes 3m long

Elbows 1.4m long and at an angle of 45 degrees

Available in diameter fi 55mm, fi 75mm, fi 90mm and fi 125mm

The auger

Gearmotor rotates a flexible helical inside the feeder, transporting feed from the silo to the chutes of the longitudinal feed system

The size of the auger fits to the cross conveyer:

FA 55 – auger fi 38mm

FA 75 – auger fi 60mm

FA 90 – auger fi 71mm

FA 125 – auger fi 95mm

Auger is made of high quality metal

Available in standard length 100m or cut to length for individual orders

Feed discharge

In the conveyor pipes are outlet drops with shut-offvalve that can open and close the feed flow along telescopic pipes 1m+1m or 1m+3 or along drop tube to the hoppers of feeding lines

The telescopic tubes and the flexible hose, which connects them with conveyor pipes, are transparent for better control of the correct feed flow

Available diameters of telescopic tubes:

70/75

75/80

80/85

82/85 - reinforced

85/90

Power unit

The power of power unit, which moves the auger, must be matched to cross conveyor diameter:

FA 55 - 0.55kW

FA 75 - 0.75kW

FA 90 - 1.1kW or 1.5kW

FA 125 - 1.5kW or 2.2kW

and connected with a gearreducer 1:3,94 or 1:2,95. The gear reducer is connected with the auger through the shaft of control unit

The motors of power unit are made of strong and durable components with high efficiency and low noise level

Control unit

On one side the control unit is connected with power unit and it controls his work with mechanical flap sensor

On the other side it is connected to PVC pipes by a plastic or metal flange matching the diameter of the PVC pipes

At the bottom there is a plastic outlet fi 75 in yellow color or plastic outlet fi 80 transparent, which connects to the telescopic pipes through a flexible hose

The cover of control unit is made of stainless steel

Control

The cross conveyor motor is automatically switched on/off when the last hopper of the feeding line is filled or emptied, thanks to a sensor located there, which sends a pulse to the motor

In an emergency the motor is switched off by a mechanical flap sensor in the control unit, which cuts off the power supply to the motor

This solution effectively protects the feeding system from any breakdown and the transport and level of feed is under control